Actuators are widely used in different fields of human activity, being modified to suit the specific needs of many different situations. Today we’re talking about one such modification – actuators designed to be used in underwater machinery.

But first of all, let’s make some definitions clear.

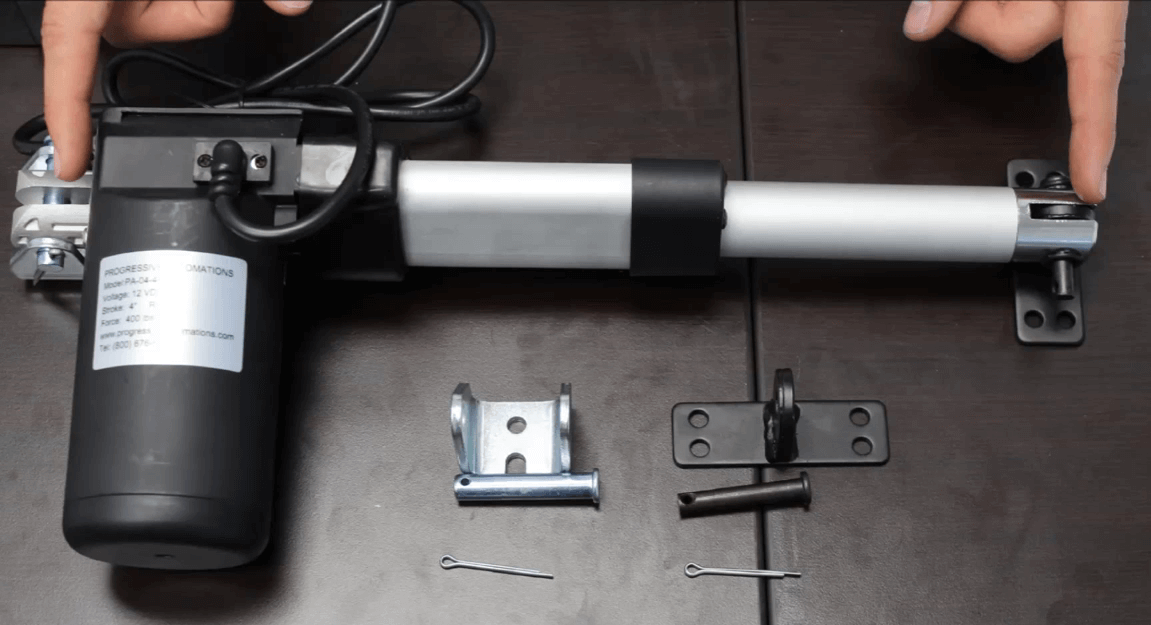

What Is A Linear Actuator

An actuator is a mechanism that creates motion, plain and simple. A linear actuator is a type of actuator that creates motion in a straight line.

Actuators became a part of our everyday life a long time ago. They’re making the industrial production of goods possible, car hydraulics won’t function without actuators, and we’re not even talking about really complex machines such as planes. Even right now you’re probably surrounded by all kinds of actuators – from the valves at your house or office to the microactuators in your phone.

However, today we’re talking about a specific kind of actuators: those designed to work underwater.

When An Actuator Needs To Be Waterproof

There are two cases when you’ll need to make your actuator waterproof – either if it’s going to be used in some sort of underwater mechanism, or if it’s going to be exposed to water from time to time (during regular cleaning process, for example).

“Underwater” Actuators

The main differences that set “underwater” actuators apart from the rest come from the different environment where they’re designed to function. They’re required to function properly despite the constant exposure to harsh conditions deep underwater – low temperature, high pressure, etc.

Waterproof Actuators

Waterproof actuators are far simpler. Simply using the right rustproof alloy is usually enough to have them withstand water exposure without any damage.

Choosing The Right Waterproof Actuator

The main requirements for waterproof actuators are:

-

- 1. Being waterproof – This one is pretty obvious. The actuator must have some sort of shell that will protect its parts from the corroding effects of water. If the actuator isn’t going to be used in some deep-sea mechanism, that’s really all that you have to worry about.

-

- 2. Temperature & pressure – If an actuator is to be used underwater, it must be designed to withstand low temperature and high pressure. The pressure is easily handled by the protective shell, but it must still be taken into account as it will impact the movements of the actuator. The temperature can also be an obstacle to the actuator’s functioning, and require the usage of special alloys.

- 3. Handling different thermodynamics – Underwater environment has its own benefits for the actuator. Water is far more efficient at transferring heat than air is, so one of the main problems of standard actuators can easily be solved here. Waterproof actuators can safely produce 2-3 times more heat, which allows the construction of far more potent actuators.

Conclusion

Modern actuators can be adapted to any environment necessary, and water is no exception. Pay attention to specific requirements above, and select your actuator carefully.

Want to choose a waterproof actuator for your own project? On our website 12vactuators.com you’ll find all sorts of actuators along with more helpful articles and guides.

Related read: How to Use a Linear Actuator