The realm of cleanliness and maintenance has dramatically changed over the years, with an increasing shift towards automation and innovative methods. One such groundbreaking technique is the Industrial Laser Cleaning Technology. But what exactly is this technology?

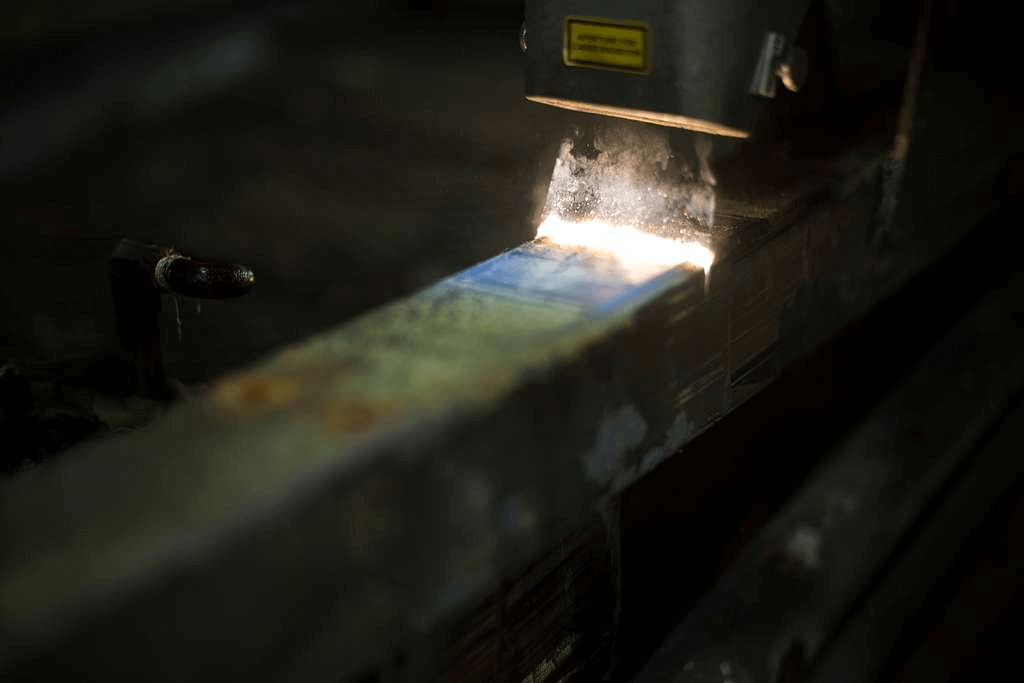

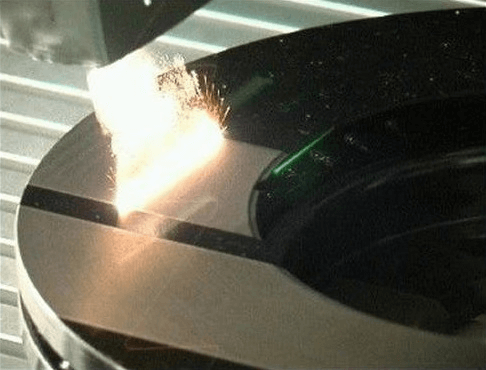

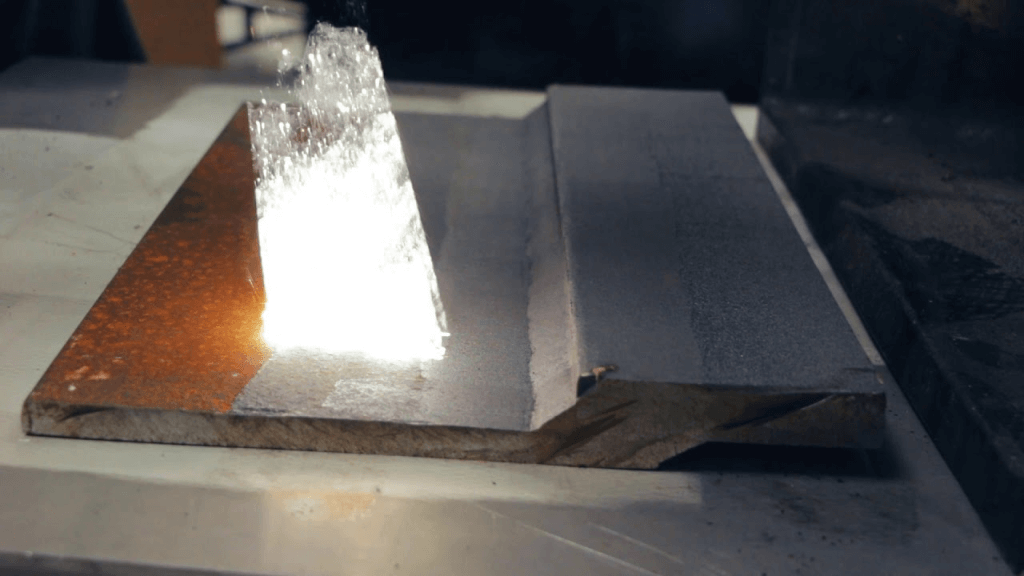

Industrial Laser Cleaning Technology (also commonly referred to as Laser Ablation) is a non-contact, non-abrasive cleaning process where lasers are used to remove contaminants, rust, coatings, oxides, and other impurities from the surface of various materials. It is becoming increasingly popular due to its effectiveness, precision, and eco-friendliness.

The Emergence of Laser Cleaning: A Historical Perspective

To appreciate the sophistication of the current laser cleaning technology, let’s trace back to its roots.

In the mid-1960s, shortly after the discovery of the laser, scientists and engineers started exploring the potential of these highly focused beams of light. Initial experimentation led to the application of lasers in medicine and manufacturing. It wasn’t until the 1980s that lasers began to be used for cleaning purposes, with early applications primarily focusing on delicate tasks such as removing soot from artwork or contaminants from fragile historical artifacts.

Progression and Advancements in Laser Cleaning

The industrial application of laser cleaning started gaining momentum in the 1990s. However, it was not until the 21st century when significant breakthroughs took place.

One such advancement was the development of fiber lasers. Prior to this, the technology used solid-state lasers which were bulky, expensive, and required significant maintenance. Fiber lasers, on the other hand, offered a compact, more efficient, and less maintenance-intensive solution, making them more suitable for industrial applications.

The introduction of Q-switched lasers in the early 2000s marked another milestone. These lasers allowed for the control of pulse durations, enabling more precise cleaning with minimal heat damage to the substrate.

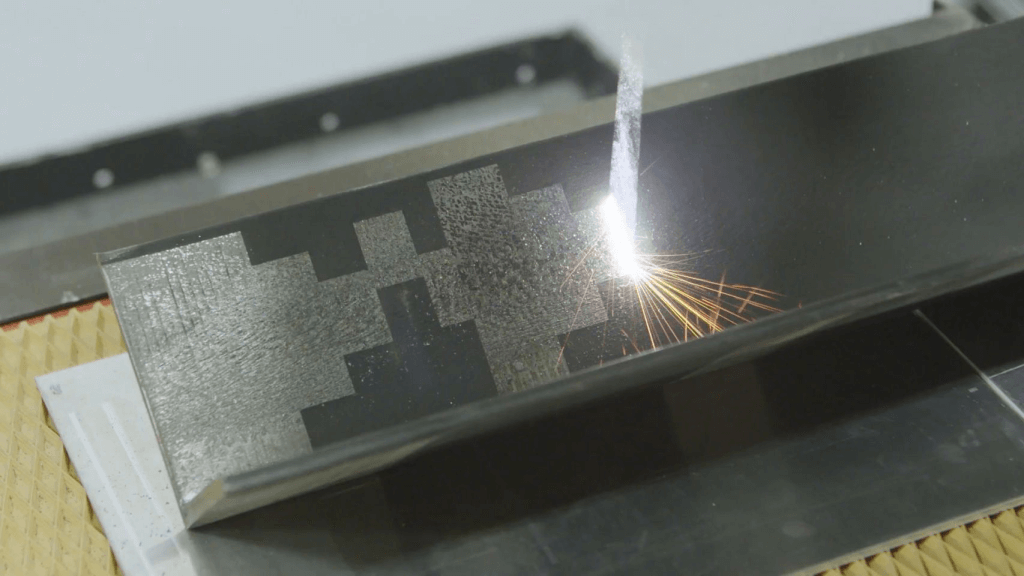

The last decade has also seen the advent of automated laser cleaning systems. These utilize robotics and advanced imaging technologies to automate the cleaning process, greatly improving efficiency and precision.

The Impact of Laser Cleaning Technology on Various Industries

Industrial Laser Cleaning machines has demonstrated its versatility by making inroads into various sectors. Each industry presents unique cleaning challenges, and laser technology has proven to be adaptable and effective.

In the automotive sector, for example, laser cleaning is used to remove rust and prepare surfaces for painting or welding. The aerospace industry uses lasers for mold cleaning and the removal of oxides and residues. In the medical field, the technology helps sterilize surgical tools and implants.

In all these industries, the benefits have been substantial:

Increased Efficiency: Laser cleaning is faster than traditional methods, improving productivity.

Improved Quality: Laser cleaning provides superior results with no damage to the substrate.

Environmental Impact: This method is eco-friendly, as it uses no chemicals and produces minimal waste.

The Future of Industrial Laser Cleaning Technology

While the advancements in laser cleaning technology over the past few decades have been impressive, there is room for further progress. For instance, the development of more compact and energy-efficient systems could further extend the reach of this technology.

Similarly, ongoing research into tuning laser parameters may lead to even more precise and adaptable cleaning solutions.

The future might also see greater integration of AI and Machine Learning. This could enable smarter, more autonomous cleaning systems capable of learning and improving over time.

Unleashing the Power of Industrial Laser Cleaning Technology

Industrial Laser Cleaning Technology, despite its considerable advancements, is yet to be fully exploited. Some of its attributes like precision, eco-friendliness, and non-contact nature make it uniquely suited for specific tasks that traditional cleaning methods struggle to accomplish.

For instance, laser cleaning has shown immense potential in the realm of cultural heritage preservation. The delicate nature of artifacts and artwork necessitates a cleaning approach that does not risk any physical damage. Laser cleaning, with its controllable parameters and non-contact nature, fits the bill perfectly.

Furthermore, the nuclear industry, where contaminants can be radioactive, could also significantly benefit from this technology. Laser cleaning offers a method to decontaminate radioactive materials without the need for human contact, greatly reducing the risk of exposure.

The Economic Implications of Laser Cleaning Technology

The implementation of Industrial Laser Cleaning Technology can also lead to economic benefits, particularly in the long run. Although the initial investment might seem high compared to conventional methods, the benefits of laser cleaning often outweigh the costs.

The main economic advantages of laser cleaning include:

Lower Operating Costs: Laser cleaning eliminates the need for consumables and reduces waste disposal costs, leading to significant savings.

Increased Productivity: As laser cleaning is typically faster than conventional methods, it boosts productivity, thus increasing economic output.

Enhanced Product Lifespan: By ensuring a high-quality cleaning process that does not damage the substrate, laser cleaning can extend the lifespan of products, saving replacement costs.

Overcoming Challenges in Industrial Laser Cleaning

Despite the promising features and potential benefits of laser cleaning, the technology faces some challenges that need to be addressed for it to gain more widespread adoption.

One such challenge is the need for comprehensive operator training. Handling laser cleaning equipment requires specific skills to ensure safety and efficiency. Lack of adequately trained personnel can be a barrier for some companies.

Another challenge is the initial investment cost. While the long-term benefits can offset the upfront expenses, for some smaller businesses, the high initial cost can be prohibitive.

However, as technology continues to advance, it is expected that the cost of laser cleaning systems will decrease, making it more accessible for businesses of all sizes.

Conclusion

The evolution of Industrial Laser Cleaning Technology from a nascent concept to a robust cleaning solution illustrates the power of technological innovation. It has redefined the benchmarks for efficiency, precision, and environmental friendliness in the cleaning industry.

Despite the challenges, the potential benefits of laser cleaning technology — in terms of quality, productivity, and environmental impact — make it a compelling proposition. As the technology continues to evolve, it is expected to be more accessible and prevalent in various sectors worldwide.

This journey through the evolution of laser cleaning technology should leave us optimistic about the future. It offers a glimpse of the potential that innovative technologies possess in shaping industries and making processes more efficient, sustainable, and effective. As we move forward, we can anticipate witnessing more such transformations, underlining the significance of continuous innovation and technological progress.