Cooling tower are widely used in the world to cool water at low cost using evaporation. Cooling towers mostly used in oil refineries, Petrochemical, Chemical, thermal power plants and in HVAC systems for cooling purpose. Cooling tower used to cool the water.

Cooling towers come in different configurations depending upon the flow of air and water. They should be chosen properly to get high efficiency. Supply of water is one of the major impacts for the cooling towers.

How Do Cooling Towers Work Explanation

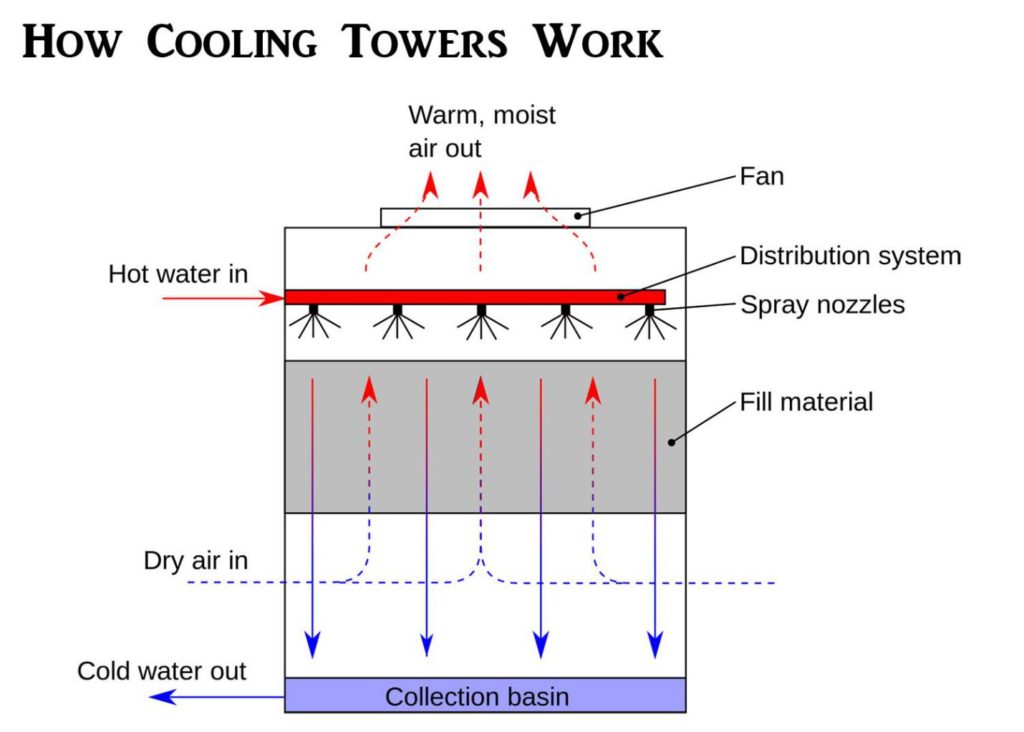

Cooling towers are device that allows continuous contact of air and water with one another to lower the temperature of the recent water. Throughout the cooling system operating method, little volumes of water evaporate.

In a short outline, the aim of a cooling system is to chill down water that gets heated up by industrial instrumentation and processes. Water comes within the cooling system hot (from industrial process) and goes out of the cooling system cold (back into the economic process). Here we tend to discover that there are 2 types of cooling tower you can use as

Natural and Forced draft:

Natural draft:

They use a fan at the top of the tower to pull the air upward at the discharge of the cooling tower. Air has high velocity at outlet and low velocity at inlet.

Forced draft:

They use a blower type fan in the cooling tower at the entrance which cause high velocity at the inlet and low velocity at outlet. It can cause circulations of air at the outlet.

- The other disadvantage of this system is that it uses much more horse power that draft type.

- The advantage of the system is that is used for high tail pressure work.

What are the major parts of cooling tower you should know?

Cooling tower consist of many components as such as

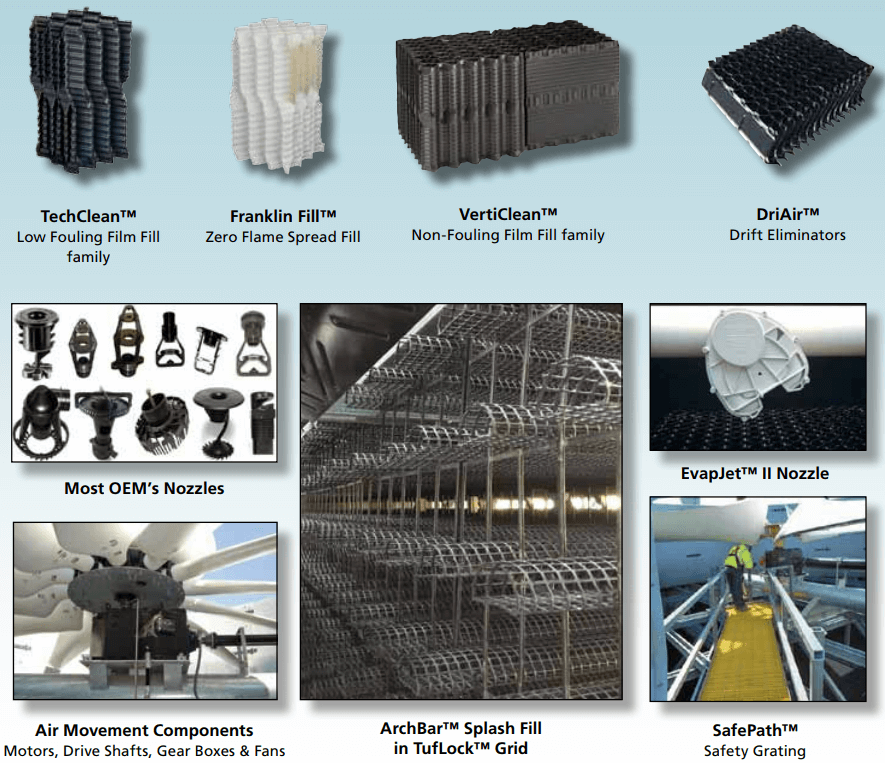

Packing of cooling tower

The packing of the cooling tower is most important cooling tower parts. It should be able to withstand the load and other environmental effects.

Fan and gears

These components are the heart of the system as fan causes the air to move. It also responsible for enhancing the rate of heat transfer in cooling tower.

Drift separator

In cooling towers there is a loss of water due to the evaporation process in the exhaust. Drift eliminator is designed to capture water droplets in air stream. This prevent the water losses in the cooling tower.

Water distribution system

Water distribution consist of nozzles, pipes, drains, valves etc. they control the flow of water in the system and responsible for proper distribution of the system.

Air intake louvers

These are the extra components for the proper running of the cooling tower. These avoid the entering of sunlight, noise and other hazardous things to enter into the cooling tower.

Control instruments for level and temperature measurement

Cooling towers has a number of level control and other temperature measurement control system.

Nozzles

Cooling tower have nozzles that directs the water into the fillers. Uniform distribution of water at the top of the filler is necessary to get proper wetting of the filler surface. Nozzle could be fixed or might have round or square patterns or can be part of the rotating assembly.

They disperse the water evenly across the heat exchanger. Nozzles are mostly made of PVC, glass or ceramics. Some nozzles are high temperature resistant. They are used in both crossflow as well as counterflow cooling towers.

Benefits of nozzles:

- Equally distribution of water.

- Reliable than other distribution system.

- Comfortable to install.

- Most efficient method.

- Lower operational cost.

Why we consider Forced Draft Cooling Tower as one of best unit for cooling systems?

- Forced draft towers shows a versatile, powerful however economical cooling technology appropriate for the foremost of business and industrial sectors.

- We have a tendency to produce forced draft cooling system that supported specific client desires, and that they go with needed parameters, native conditions, water quality, and alternative specific conditions at the installation area.

- A counterflow of air and cool water in the cooling fill results in a heat transfer.

- The flow of air is provided by a propelling mechanical device fan whereas the drift eliminators forestall the transfer of little the tower area.

- You can conclude that benefits of force draft cooling towers over natural draft: For the identical capability of usage, Force drafts are smaller than the natural draft cooling towers. That’s because of cooling capability will increase as increase in volume of intake air, that is forced out by propelling fan.

- Thousands of natural draft cooling towers are employed, in America and Europe, as cooling systems for power plants or others as counter measure against Thermal-pollution.

- Recently in Japan, demands for cooling system systems are increasing remarkably with the development of huge power plants.

Some Industrial applications you can consider with Force Draft Towers are:

- Energy and Power Sector

- Petroleum based industries

- Pharmaceutical and chemical industries

- Engineering & metallurgical Sectors

- Rubber and Plastic industry

- Textile and paper industry

- Manufacturing departments (food processing, sugar refining)

Conclusion:

- We have discussed what a cooling tower is how it works with you.

- Then you got the idea of different parts of Cooling tower and their individual functions.

- Thus cooling tower, a device, that cools down processed water coming from Power plant, Manufacturing or Heat treatment region, Building or any confined space, where you want to supply cool volume of water.

- Forced Draft has is more efficient than natural draft however initial cost and operating budget are high but it deliver more better results.

- Working principal of Forced Draft Towers is being discussed with you.

- The rate of decrease in temperature you want to acquire will suggest the size, Capacity and build of material of your cooling tower.

- Cooling is consider cheap source of water cooling treatment on large industrial scale rather than utilizing costly Chillers or other system which is also not environmental friendly.

- As discussed develop countries are now looking forward for cheap Eco-friendly cooling system considering Cooling towers as its source.