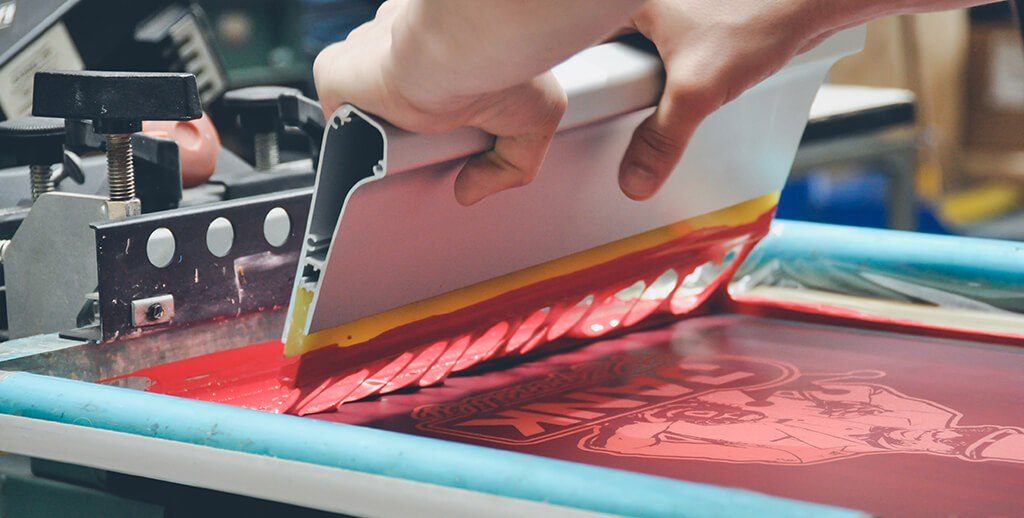

When one takes a comprehensive look at the industry of printing, he may think that this field is fairly straightforward. However, complications arise because products are custom made to meet the needs of the customer’s specifications. Blockages happen. Misprints take place. To your peers and family members, you are purely a t-shirt printer. What could perhaps go wrong?

Deep down you may wince while thinking about those 200 various complications that are likely to arise during the production of an order. You must have been in places where disaster strikes, and many times you find yourself reacting to issues, by executing new regulations into your store as things keep coming up. Rather than looking for solutions to the problems that may have cost you your precious money and time, let us look at 7 ways to improvise your workflow.

#1: Keep Experimenting

Your workflow can never be perfect. Be nimble, flexible, and willing to change it on the basis of how good your workflow is functioning at your store/shop. If things do not seem to go well, spend time testing, adapting, and changing the new workflow. You may discover those strange nuances in your store that work better for your business. However, workflow management software can help teams reduce bottlenecks in the workflow. In addition, the integration of web to print software can optimize printing processes and enhance operational efficiency.

#2: Estimate Costs

Break down expenses that are associated with every department. This way, you will be able to find your cost per impression. By working out these expenses, you can move around or allocate labor to boost up various processes.

#3: Reward the Team

The jobs that are taken care of properly and on time properly deserve rewards. Create incentives for these. In the same way as a shop handles protection in manufacturing, create a board that says it has been so and so time since a misprinted job.

#4: Keep a Digital Track of Your Order

Papers are likely to get lost, which is why we now live in the cloud. Make sure you have digital records of all communications with the customer. In addition, use Screen Printing Software that is ideal for your work.

#5: Form Departments

Your store must be broken down into several various departments using statuses that are directly related to their role. There could be shipping, production, pre-press, art, and sales department. Make them personal according to your business.

#6: Track Time

Go for a few orders per week and look at how rapidly they go through different departments. Consider all the blockages and evaluate them.

#7: Make Your Team Communicate

Every day, your team must group and go through their workflow. They must also reflect on how they manage their jobs. In a similar way the nurses talk to doctors prior to surgery, ensure you have open communication channels.

Screen printing workflow management can only be enhanced when you, as a proprietor, take the business seriously and have the willingness to find out the bottlenecks and correct errors. When you start evaluating the process, your business will go without any faults.

You may also like to read: